Showing posts with label battery. Show all posts

Showing posts with label battery. Show all posts

Friday, December 12, 2014

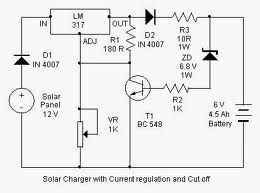

Solar Battery Charger Circuit Schematic

Here is a solar charger circuit that is used to charge Lead Acid or Ni-Cd batteries using the solar energy power. The circuit harvests solar energy to charge a 6 volt 4.5 Ah rechargeable battery for various applications. The charger has Voltage and Current regulation and Over voltage cut off facilities.

Wednesday, November 19, 2014

NIMH battery charger

Series NIMH Battery Charger with IC LT4060 is a NIMH battery charger is powerful, effective and efficient. Featur owned by IC LT4060 is a specialization of a NIMH battery charger. NIMH Battery Charger with IC LT4060 can perform safely charging NIMH batteries because it comes with a battery temperature protection is in charge and the peak level detection system of the battery voltage is in charge. Battery temperature protection system from the excessive use of NTC temperature sensor. Series NIMH Battery Charger with IC LT4060 also features a charging indicator that will light up when charging and will die when the battery is full. IC 4060 used in this NIMH battery charger from Linear Technology is a production that is designed special for NIMH battery charger.

Image Series NIMH Battery Charger with IC LT4060

Description Series NIMH Battery Charger with IC LT4060

R2 potentiometer used for setting the maximum temperature (at set at the value of 4K)

LED D1 is a battery charging indicator

Charger Power Transistor (Q1) can be replaced with PNP transistors are capable of a current of 3A - 5A

Monday, November 17, 2014

LM3914 IC based on Simple Battery Tester

This LM3914 IC based on Simple Battery Tester is very simple to explain:

Once the test switch is pushed, the Car battery voltage is supply into a high impedance voltage divider. His function is to divide 12V to 1, 25V (or lower values to reduced values). This solution is much better than enabling the internal voltage regulator set the 12V sample voltage to be feed into the internal voltage divider simply because it cannot regulate 12V if the voltage falls lower (linear regulators only step down). Simply wiring with no change, the regulator provides secure 1, 25V which can be fed into the precision internal resistor cascade to create sample voltages to the internal comparators.

In any case the default establishing let you to determine voltages between 8 and 12V however you can measure even from 0V to 12V setting the offset trimmer to 0 (but i believe that below 9 volt your vehicle would not start). There is a smoothing capacitor (4700uF 16V) it is used to adsorb EMF noises produced from the ignition coil if youre testing the battery during the engine working. Diesel engines would not need it, but i am not sure. If you want more a level graph rather than a bar graph simply disconnect pin 9 on the IC (MODE) from power. The calculations are usually simple (default).

Monday, November 3, 2014

A Car Battery Monitor

A close call on the road can really focus your mind on the importance of having a battery monitor in a car. I had been enjoying a pleasant week of travelling around the countryside at a leisurely pace and taking in the beautiful scenery each day. It wasnt until the final day, with the big rush to return home, that I had to drive at night.My home is deep in the country and on the road I was travelling the closest petrol station may be 80km away. I was travelling through an area that is full of open-cut coal mines and large heavily loaded semi-trailers constantly pound the roads, travelling at quite high speeds. It was around 8pm at night and everything was very dark no street lights or house lights anywhere.

Just as I was going up a hill, the lights began to dim and the engine coughed. A large semi-trailer loomed in the rear-vision mirror as I pushed the clutch in and tried to restart. My speed was falling rapidly and my lights were blacked out - I was like a sitting duck in the middle of the road, as the semi-trailer came rapidly bearing down on me.

I just managed to pull the car off the road, as the semi-trailer came screaming past, missing me by inches! After calling for assistance from the NRMA, the problem was found to be a fault in the alternator, which was failing to charge the battery. The battery voltage had been falling under the heavy load of the lights and at the worst possible time, there was not sufficient power for the lights or the motor.

After the initial shock wore off, I put on my thinking cap to come up with a PIC-based solution to the problem. What was really needed was a display and a buzzer, to get my attention should the voltage fall outside a specified range. So my design criteria was set, a series of LEDs could indicate the voltage and a buzzer would also be used to warn of problems.

Main Features:

- Visual indication of battery voltage

- Audible warning when voltage becomes low

- Screw terminals for easy connection

- Simple and easy to build

Circuit details:

The circuit is based on PIC16F819 18-pin microcontroller which has an analog-to-digital (A/D) input to monitor the battery voltage and outputs capable of driving LEDs directly, to keep the component count down. There are seven LEDs in all, giving a good range of voltage indication. The topmost LED, LED1, comes on for voltages above 14V which will occur when the battery is fully charged. LED2 indicates for voltages between 13.5V and 14V while LED3 indicates between 13V and 13.5V.

Normally, one of these LEDs will be on. LED4 covers 12.5V to 13V while LED5 covers 12V to 12.5V. LED6 covers from 11.5V to 12V while LED7 comes on for voltages below 11.5V. These two LEDs are backed up by the piezo chime which beeps for voltages between 11.5V and 12V and becomes more insistent for voltages below 11.5V.

That might seem fairly conservative. After all, most cars will start with no troubles, even though the battery voltage might be a touch below 12V, wont they? Well, no. Some modern cars will happily crank the motor at voltages below 11V but their engine management will not let the motor start unless the voltage is above 11V.

So dont think that a modern car will always start reliably. This little battery monitor could easily prevent a very inconvenient failure to start! So lets describe the rest of the circuit. The incoming supply is connected via diode D1 which provides protection against reverse polarity while zener diode ZD1 provides protection from spike voltages.

A standard 7805 3-terminal regulator is then used to provide a stable 5V to the microcontroller. The battery voltage is sensed via a voltage divider using 33kΩ and 100kΩ resistors. This brings the voltage down to within the 0-5V range for the A/D input of the PIC16F819. Port B (RB0 to RB7) of the microcontroller is then used to drive the various LEDs, with current limiting provided via the 330Ω resistor network. RB7, pin 13, drives a switching transistor for the piezo buzzer.

Software:

For the software, the design follows the basic template for a PIC microcontroller. Port A and its ADC (analog-to-digital converter) function are set up while port B functions as the output for the LEDs and buzzer. Once the set-up is complete, a reading will be taken at port RA2, the input for the A/D convertor. This reading is then compared with a series of values to determine the range of the voltage. This is similar to a series of "if" statements in Basic language.

If the voltage is found to be within a certain range, the relevant port B pin will be turned on. If the voltage is below 12V, the buzzer will be turned on for a brief period, to signal a low battery condition. As the voltage falls below 11.5V, the frequency of the beeps will increase, to signal increased urgency.

Building it:

All the parts are mounted on a small PC board measuring 46 x 46mm (available from Futurlec). The starting point should be the IC socket for the PIC16F819, as this is easiest to mount while the board is bare. The next item can be the PC terminal block. The resistors and capacitors can then follow. Make sure the electrolytics are inserted with correct polarity.

Make sure that you do not confuse the zener (ZD1) with the diode when you are installing them; the diode is the larger package of the two.

Even more important, dont get the 78L05 3-terminal regulator and the 2N3906 transistor mixed up; they come in identical packages. The 78L05 will be labelled as such while the 2N3906 will be labelled "3906". And make sure you insert them the correct way around. The buzzer must also be installed with the correct polarity. The 330Ω current limiting resistors are all in a 10-pin in-line package. There are four green LEDs, two yellow and one red. They need to be installed in line and with the correct orientation.

Testing:

Before you insert the PIC16F819 microcontroller, do a voltage check. Connect a 12V source and check for the presence of 5V between pins 14 & 5 OF IC1. If 5V is not present, check the polarity of regulator REG1 and the polarity of the diode D1. If these tests are OK, insert the IC and test the unit over a range of voltage between 9V and 15V. Make sure that all LEDs come on in sequence and the piezo buzzer beeps for voltages below 12V.

Now it is matter of installing the unit in your car. It is preferable to install the unit in a visible position for the driver. However, it should not obscure any other instruments. The unit should be connected to the cars 12V supply after the ignition switch. This will turn the unit off with the other instruments and prevent battery drain while the motor is not running.

Tuesday, October 28, 2014

Circuit 3 LED battery monitor

This is the circuit diagram of a 3 LED bar graph type battery monitor circuit that is ideal for monitoring the voltage level of an automobile battery.When battery voltage is 11.5V or less transistor Q1 will be On and the LED D1 will be glowing.When battery voltage is between 11.5 and 13.5V, the transistor Q2 will be On and the LED D2 will be glowing.When battery voltage is above 13.5V the transistor Q3 will be On and the LED D7 will be glowing.

Circuit diagram with Parts list.

Notes.

Assemble the circuit on a general purpose PCB.The battery to be monitored can be connected between the terminals namely A and B.It is always better to use LEDs of different colour.

Thursday, October 23, 2014

LM350 12 Volt Battery Charger

The battery circuit scheme is designed as a source of constant voltage with negative temperature coefficient. Transistor Q1 (BD 140) is used as a temperature sensor. transistor Q2 is used to prevent the battery from discharging through R1 when electrical power is unavailable. Charging circuit is designed based on the LM350 voltage regulator IC. The output voltage of the charger can be adjusted between 13-15 V by varying the POT R6.

LM350 will try to keep the voltage drop between the input pin and output pin at a constant value of 1.25V. So there will be a constant current flow through resistor R1. Q1 act here as a temperature sensor with the help of R6/R3/R4 components that are more or less controls the base current of Q1. As connection emitter / base of transistor Q1, the same as other semiconductors, containing the temperature coefficient of-2mV / ° C, the voltage output will also show a negative temperature coefficient. This one is just a factor of 4 large, because the variation of the emitter / base of Q1 is multiplied by a factor of division P1/R3/R4. This leads to some-8mV / ° C. LED will light whenever power is available.

Thursday, September 18, 2014

Versatile Micropower Battery Protector

Protect your expensive batteries from discharge damage with this mini-sized electronic cutout switch. It uses virtually no power and can be built to suit a wide range of battery voltages.

Main Features

- Disconnects load at preset battery voltage

- Automatically reconnects load when battery recharged

- Ultra-low power consumption (<20ma)

- Miniature size

- 10A maximum rating

- Suitable for use with 4.8-12.5V batteries

- Transient voltage protection (optional)

Suitable for use in...

- Cars, boats & caravans

- Security systems

- Emergency lighting

- Small solar installations

- Camera battery packs

- Many other low-power applications

Back in May 2002, we (Silicon Chip) presented the "Battery Guardian", a project designed specifically for protecting 12V car batteries from over-discharge. This unit has proven to be very popular and is still available from kit suppliers. This new design does not supersede the Battery Guardian – at least not when it comes to 12V car batteries. Instead, it’s a more flexible alternative that can be used with a wide range of battery voltages.

In this new "Micropower Battery Protector", we’ve dispensed with the low-battery warning schemary and the relatively cheap N-channel MOSFET used in the Battery Guardian in favour of a physically smaller module that steals much less battery power. It costs a little more but can switch lower voltages, allowing it to be used with 6V & 12V lead-acid batteries and 4-cell to 10-cell NiCd and NiMH battery packs.

PCB layout:

Most battery-powered equipment provides no mechanism for disconnecting the batteries when they’re exhausted. Even when the voltage drops too low for normal operation, battery drain usually continues until all available energy is expended. This is particularly true of equipment designed to be powered from alkaline or carbon cells but retro-fitted with rechargeables.

Circuit diagram:

Another example is emergency lighting and security equipment designed to be float-charged from the mains. In an extended blackout period, the batteries can be completely drained and may not recover when the mains power is finally restored.

Source: Silicon Chip 27 July 2004

Wednesday, September 10, 2014

12 V Battery Charger Wiring diagram Schematic

This is a simple12 V Battery Charger Circuit Diagram is a high performance charger for gelled electrolyte lead-acid batteries. Charger quickly recharges battery and shuts off at full charge. Initially, charging current is limited to 2A. As the battery voltage rises, current to the battery decreases, and when the current has decreased to 150 mA, the charger switches to a lower float voltage preventing overcharge.

12 V Battery Charger Circuit Diagram

When the start switch is pushed, the output of the charger goes to 14 V. As the battery approaches full charge, the charging current decreases and the output voltage is reduced from 14 V to about 12 5 V terminating the charging. Transistor Ql then lights the LED as a visual indication of full charge.

Monday, September 8, 2014

Battery Discharger Using Discrete Components

The battery discharger published in this website may be improved by adding a Schottky diode (D3). This ensures that a NiCd cell is discharged not to 0.6–0.7 V, but to just under 1 V as recommended by the manufacturers. An additional effect is then that light-emitting diode D2 flashes when the battery connected to the terminals is flat. The schema in the diagram is based on an astable multivibrator operating at a frequency of about 25 kHz. When transistor T2 conducts, a current flows through inductor L1, whereupon energy is stored in the resulting electromagnetic field. When T2 is cut off, the field collapses, whereupon a counter-emf is produced at a level that exceeds the forward voltage (about 1.6 V) of D2.

A current then flows through the diode so that this lights. Diode D1 prevents the current flowing through R4 and C2. This process is halted only when the battery voltage no longer provides a sufficient base potential for the transistors. In the original schema, this happened at about 0.65 V. The addition of the forward bias of D3 (about 0.3 V), the final discharge voltage of the battery is raised to 0.9–1.0 V. Additional resistors R5 and R6 ensure that sufficient current flows through D3. When the battery is discharged to the recommended level, it must be removed from the discharger since, in contrast to the original schema, a small current continues to flow through D3, R2-R3, and R5-R6 until the battery is totally discharged.

The flashing of D2 when the battery is nearing recommended discharge is caused by the increasing internal resistance of the battery lowering the terminal voltage to below the threshold level. If no current flows, the internal resistance is of no consequence since the terminal voltage rises to the threshold voltage by taking some energy from the battery. When the discharge is complete to the recommended level, the LED goes out. It should therefore be noted that the battery is discharged sufficiently when the LED begins to flash.

Sunday, September 7, 2014

Lead Acid Battery Protector

The schema described here can be used to ensure that a 12 V sealed lead acid (SLA) gel battery isn’t discharged too deeply. The principal part of the schema is a bistable relay, which is driven by the output of an op amp.

Lead Acid Battery Protector Circuit Diagram

The battery voltage is first reduced via D1, R1, P1 and R2, and then continuously compared with a reference voltage set up by diode D2. When the battery discharges too much and its terminal voltage drops below the level set by P1, the output of the opamp becomes High, which causes the relay to toggle. This in turn isolates the load from the battery. The battery can be reconnected via S1 once the battery has been replaced or recharged.

The relay used in the prototype is a 5 V bistable type made by Omron (G6AK-234P-ST-US 5 VDC). The two windings of the relay each have a resistance of 139 Ω (for the RAL-D 5 W-K made by Fujitsu this is 167 Ω). When the battery voltage starts to become too low and the relay is being reset the current consumption of the schema is about 45 mA. Shortly after the load has been disconnected, when the battery voltage rises above the reference voltage again, the reset coil will no longer be powered and the current consumption drops back to about 2.5 mA.

The range of P1 has intentionally been kept small. With a reference voltage of 5.6 V (D2) and a voltage drop of 0.64 V across D1, the schema reacts within a voltage span of 11.5 V and 11.8 V. This range is obviously dependent on the zener diode used and the tolerance.

For a greater span you can use a larger value for P1 without any problems. With the potentiometer at its mid setting the schema switches at about 11.6 V.

Author : Jürgen Stannieder

Tuesday, August 26, 2014

USB powered battery charger circuit

At this time I will share about the series used in the usb to charge battery. Issued voltage 4.7 Volt to 5 Volt DC suitable for battery charge the phone, as well as other batteries.

Below is a circuit where the voltage is removed the usb on the computer will be strengthened by several components so that the voltage used to charge batteries more powerful and filtered, and will make it more durable and long lasting.

Part List :

R1 = 1 K

R2 = 330 R

R3 = 4K7

R4 = 300 R

R5 = 27R

D1 = 4.7 volt zener /1W

C1 = 100uF/16V

Q1 = BC548

Q2 = BC558A

R3 = 4K7

R4 = 300 R

R5 = 27R

D1 = 4.7 volt zener /1W

C1 = 100uF/16V

Q1 = BC548

Q2 = BC558A

Saturday, August 23, 2014

Li Ion Battery Charger Wiring diagram Schematic

The LP2951 regulator is manufactured by National Semiconductors. The choice of values is from an application note Battery Charging, written by Chester Simpson. Diode D1 can be any diode from the 1N00x series, whichever is conveniently available. It functions as a blocking diode, to prevent a back flow of current from the battery into the LP2951 when the input voltage is disconnected. Charging current is about 100+mA, which is the internally-limited maximum current of the LP2951. For those wondering, this is compatible with just about any single-cell li-ion battery since li-ion can generally accept a charging current of up to about 1c (i.e. charging current in mA equivalent to their capacity in mAh, so a 1100mAh li-ion cell can be charged at up to 1100mA and so on).

![Li-Ion]() A lower charging current just brings about a correspondingly longer charge time. IMHO 100mA is quite low, low enough that the schema can be used for an overnight charger for many typical single-cell li-ion batteries. The resistors are deliberately kept at large orders of magnitude (tens/hundred Kohm and Mohm range) to keep the off-state current as low as possible, at about 2?A. Resistor tolerances should be kept at 1% for output voltage accuracy. The 50k pot allows for an output voltage range between 4.08V to 4.26V - thus allowing calibration as well as a choice between a charging voltage of 4.1V or 4.2V depending on the cell to be charged. The capacitors are for stability, especially C2 which prevents the output from ringing/oscillating.

A lower charging current just brings about a correspondingly longer charge time. IMHO 100mA is quite low, low enough that the schema can be used for an overnight charger for many typical single-cell li-ion batteries. The resistors are deliberately kept at large orders of magnitude (tens/hundred Kohm and Mohm range) to keep the off-state current as low as possible, at about 2?A. Resistor tolerances should be kept at 1% for output voltage accuracy. The 50k pot allows for an output voltage range between 4.08V to 4.26V - thus allowing calibration as well as a choice between a charging voltage of 4.1V or 4.2V depending on the cell to be charged. The capacitors are for stability, especially C2 which prevents the output from ringing/oscillating.

Parts List

IC1 = LP2951, voltage regulator

D1 = 1N4002, General purpose diode

R1 = 2M, 1%, metal-film

R2 = 806K, 1%, metal-film

P1 = 50K, potentiometer

C1 = 0.1uF, polyester

C2 = 2.2uF/16V, electrolytic

C3 = 330pF, ceramic

Li-Ion Battery Charger Circuit Diagram

Parts List

IC1 = LP2951, voltage regulator

D1 = 1N4002, General purpose diode

R1 = 2M, 1%, metal-film

R2 = 806K, 1%, metal-film

P1 = 50K, potentiometer

C1 = 0.1uF, polyester

C2 = 2.2uF/16V, electrolytic

C3 = 330pF, ceramic

Thursday, August 21, 2014

Simple Mobile Phone Battery Charger

Mobile phone chargers available in the market are quite expensive. The schema presented here comes as a low-cost alternative to charge mobile telephones/battery packs with a rating of 7.2 volts, such as Nokia 6110/6150.

Circuit diagram:

Mobile Phone Battery Charger Circuit Diagram

Parts

R1 = 1K

R2 = 47R

R3 = 10R

R4 = 47R

C1 = 1000uF-25V

D1 = LEDs any color

D2 = LEDs any color

D3 = LEDs any color

D4 = 1N4007

D5 = 1N4007

IC1 = LM7806

T1 = 9VAC Xformer 250mA

BR1 = Diode bridge 1A

Circuit Operation:

The 220-240V AC mains supply is down-converted to 9V AC by transformer T1. The transformer output is rectified by BR1 and the positive DC supply is directly connected to the charger’s output contact, while the negative terminal is connected through current limiting resistor R2. D2 works as a power indicator with R1 serving as the current limiter and D3 indicates the charging status. During the charging period, about 3 volts drop occurs across R2, which turns on D3 through R3.

An external DC supply source (for instance, from a vehicle battery) can also be used to energies the charger, where R4, after polarity protection diode D5, limits the input current to a safe value. The 3-terminal positive voltage regulator LM7806 (IC1) provides a constant voltage output of 7.8V DC since D1 connected between the common terminal (pin 2) and ground rail of IC1 raises the output voltage to 7.8V DC. D1 also serves as a power indicator for the external DC supply. After constructing the schema on a veroboard, enclose it in a suitable cabinet. A small heat sink is recommended for IC1.

Wednesday, August 20, 2014

Temperature Sensing Nicad Battery Charger Wiring diagram Schematic

Temperature Sensing Nicad Battery Charger Circuit Diagram .Two simple diagram permit Nicad charging of a battery based on temperature differences between the battery pack and the ambient temperature. This method has the advantage of allowing fast charging because the schema senses the temperature rise that occurs after charging is complete and the battery under charge is producing heat, not accumulating charge.

Temperature Sensing Nicad Battery Charger Circuit Diagram

Friday, August 15, 2014

Ultra Fast Battery charger circuit

Ultra Fast Battery Chager for Nickel-Cadmium battery cells [NiCad] which will be discussed in this article is Fast NiCad Battery Charger, called the Ultra Fast Charger Battery Charger NiCad because it can make filling fast NiCad Batteries Cell. A battery charger in Desai has a fast charging capabilities such as Ultra Fast Battery Chager for Nickel-Cadmium battery cells [NiCad] on this article shall be equipped with some ability to protect the battery and charger circuit itself.

Feature owned by Ultra Fast Battery Chager for Nickel-Cadmium battery cells [NiCad]

- Autoshut-off, is the ability of the charger to stop charging current to a NiCad battery if the capacity NiCad battery is fully charged.

- Polarity Protection, with the existence of this capability so if there are mounting the battery on the charger upside yan can be known.

- Constant output voltage

- Output currents enough to fill some NiCad batteries at once in parallel.

- Short Circuit Protection, with the existence of this protection circuit so if there is short-circuit caused by a battery and a charger circuit itself will not damage the other parts are not damaged.

- Series Ultra Fast Battery Chager for Nickel-Cadmium battery cells [NiCad]

Image series above is a series of schematic drawings for Ultra Fast Battery Chager for Nickel-Cadmium battery cells [NiCad]. Ultra Fast Battery Chager for Nickel-Cadmium battery cells [NiCad] can be used for 8 to 10 NiCad batteries at once with 12 volt output voltage and max current is 3.5 A. The main components in the circuit of Ultra Fast Battery Chager for Nickel-Cadmium battery cells [NiCad] is UC3843 and MC34181. UC3843 chip is a voltage regulator and M34181 is a JFET OpAmp with characteristic low offset voltage, input impedance is very high. MC34181 serves as a voltage comparator.

Tuesday, August 12, 2014

Electronic Rf Type Battery Charger Wiring diagram Schematic

This is a simple Electronic Rf Type Battery Charger Circuit Diagram. This type of charger couples RF from L2 to an external pickup coil. The pickup coil connects to a rectifier and battery to be charged. This idea is handy because no wire or contacts are required. L2 is 10T #24 wire and L3 is 10T #30 wire. Both coils are mounted on a 1 V ferrite rod.

Electronic Rf Type Battery Charger Circuit Diagram

Subscribe to:

Posts (Atom)